Stock Plastic Tubing, Extrusions & Coextrusions for Catheter Applications

Duke Extrusion maintains a large inventory of stock plastic extrusions for catheter applications. Our stock medical tubing and custom catheter tubing extrusions are available in numerous sizes, materials, and configurations. Duke Extrusions specializes in custom medical tubing, offering the shortest lead times in the industry.

Questions regarding our stock tubing and plastic coextrusion options? Call us today at 831-420-1104 or get in touch for more information on custom medical tubing produced to your project’s specifications.

Duke Stock Medical Tubing & Medical Extrusion Product Options

Duke Extrusion is a full-service contract manufacturer dedicated to providing medical device manufacturers and OEMs with the highest quality medical grade stock tubing and extrusion products for catheters and high-performance tubing applications. We specialize in medical tubing, extrusions, complete catheter assemblies, and finished goods. Duke stock medical tubing options include the following:-

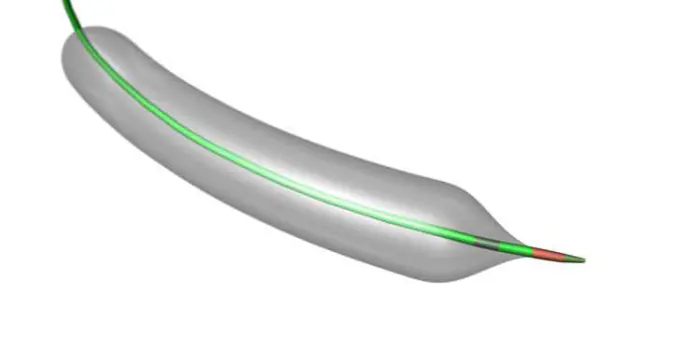

VERGO® Steerable Access Sheaths - Hydrophilic coating on OD provides very low friction to aid navigation and PTFE liner for low friction ID. Off the shelf sizes from 18Fr - 32Fr and customized configurations available soon.

-

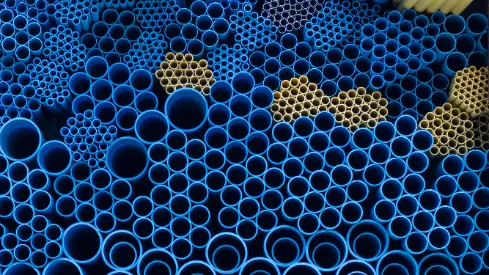

Single Lumen Tubing - Available in various materials with durometers from 35D to 80D. We stock a variety of tubing with different I.D., O.D., and wall thicknesses suitable for many catheter applications.

-

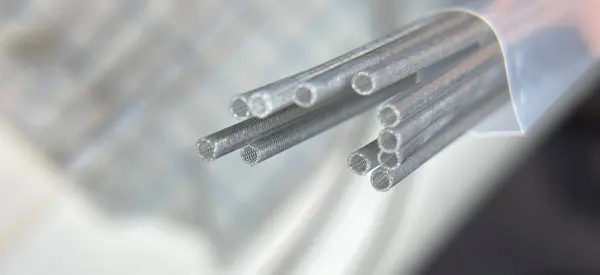

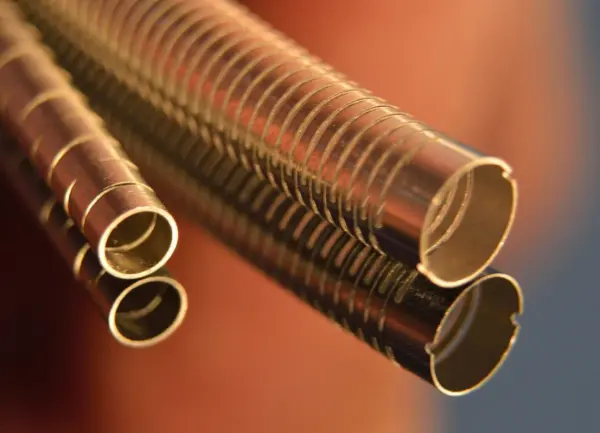

Coil Reinforced Tubing - Provides improved kink resistance, higher pressure capabilities, burst strength, improved flexibility, and additional column strength.

-

Braid Reinforced Tubing - Ideal for high-performance catheters and medical tubing applications, such as high-pressure lines and deflectable tip catheters.

-

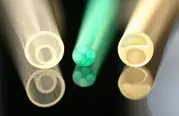

PTFE Lined Tubing - PTFE liners on the I.D. minimize friction and allow other devices to pass through with lower resistance.

-

Multi-Durometer Tubing - Combining softer and stiffer durometers along the length of medical tubing provides the flexibility and support needed to navigate difficult target locations.

-

Spectraflex R&D Kits - Contain four tubes of identical dimensions but different durometers, letting you determine which stiffness is suitable for your application.

-

Telescopic R&D Kits - Contain four tubes of various diameters which fit or nest within one another, allowing you to find the correct fit for your concentric tubing design.

-

Laser Cut Hypotube - Offers increased flexibility, better torque response, and higher hoop strength to minimize ovalization during bending. Laser cutting can also limit axial stretch and provide custom deflection properties to the tubing, such as compound curves.

-

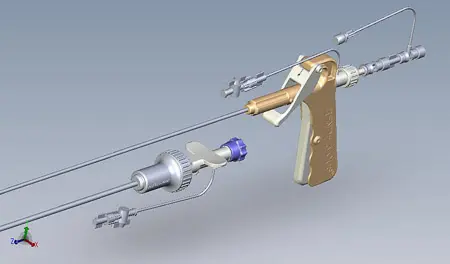

Steerable/Deflectable Catheters - These systems help guide catheters, stents, and other implant delivery systems and therapeutic devices to challenging target locations.

Medical Catheter Tubing & Extrusions for Custom Applications

Duke’s combination of coextruded materials provides a variety of unique properties. We can produce stock medical tubing and extrusions that provide an inner layer with drug compatibility and outer layer fitting application specifics such as device connections and impermeability.

As one of the industry’s leading medical tubing suppliers, we manufacture tubing and catheters that meet various unique needs. We work with you to match your design requirements for applications such as:

-

Catheters

-

Intravenous (IV) tubing

-

Fluid transfers

-

Infusion tubing

-

Nasogastric tubes

-

Anesthesia

-

Hemodialysis tubing

-

Oxygen

Duke’s Custom Co-Extrusion & Extrusion Services

With our custom coextrusion process, we can combine the beneficial properties of two materials by extruding them simultaneously into a single tube. The materials can be arranged in concentric tube-on-tube configurations or by striping the materials in a single lumen for added benefits. In multi-lumen coextrusions, we can isolate materials to specific areas of the tubing’s cross-section.

In addition to coextrusion, we also offer other custom extrusion services, including:

-

And more

Contact Duke Extrusion for Medical Plastic Tubing, Extrusions & Coextrusions for Catheter Applications Today

Get a quote for medical tube custom extrusions, or call us at 831-420-1104 to discuss custom medical tubing for your application needs. If you are looking for tubing with design specifications, check out Duke Empirical for your custom requirements.