Custom Medical Extrusion Services

Duke Extrusion can create custom medical extrusions to meet your unique requirements. We are capable of manufacturing a wide range of custom extrusions within an EN 13485 certified quality system. Every product meets the same high standards for quality and precision that our customers have come to expect.

We design and produce in-house custom tooling within a dedicated machining center to support the complete custom extrusion design for R&D and production runs. We provide the industry’s fastest possible lead times for custom medical extrusions. When needed, our design team can assist in refining your designs for optimum performance and manufacturability. Nearly every aspect of your tubing can be customized to match your exact specifications. Get a quote for custom extrusions. Questions? Call us today at 831-420-1104!

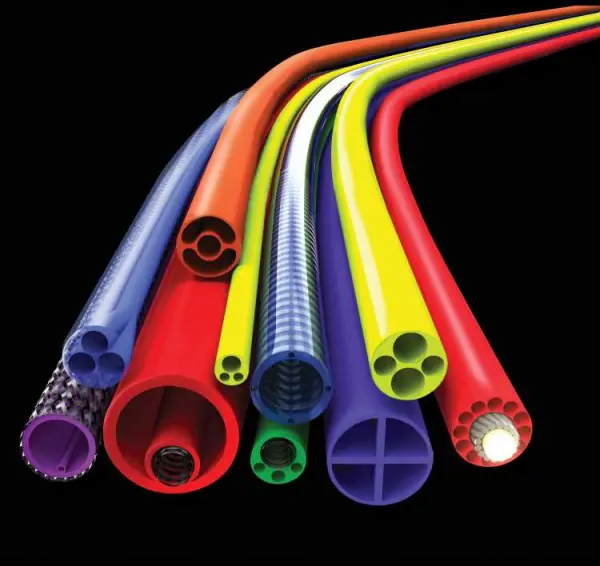

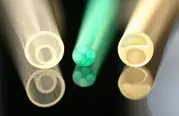

Duke Extrusion’s custom medical extrusion services include:

- Custom Single Lumen Tubing

- Multi-Lumen Tubing

- Taper/Bump Tubing

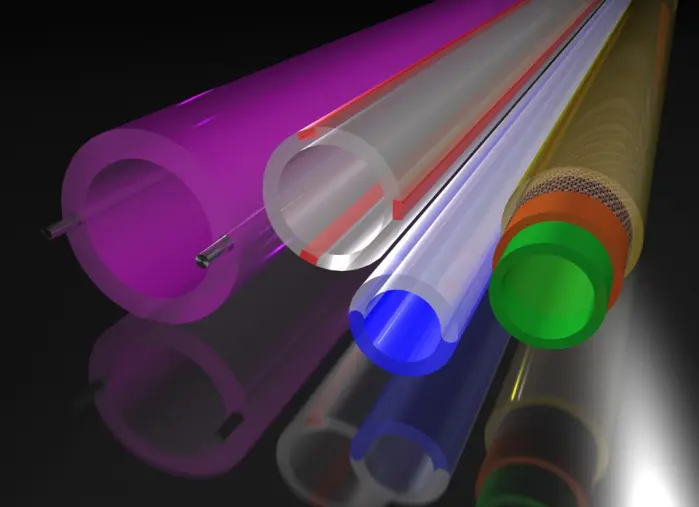

- Overjacketing

- Solid Rod Extrusions

- Custom Profile Co-Extrusions

- and more

Available features and capabilities of our custom medical extrusions include:

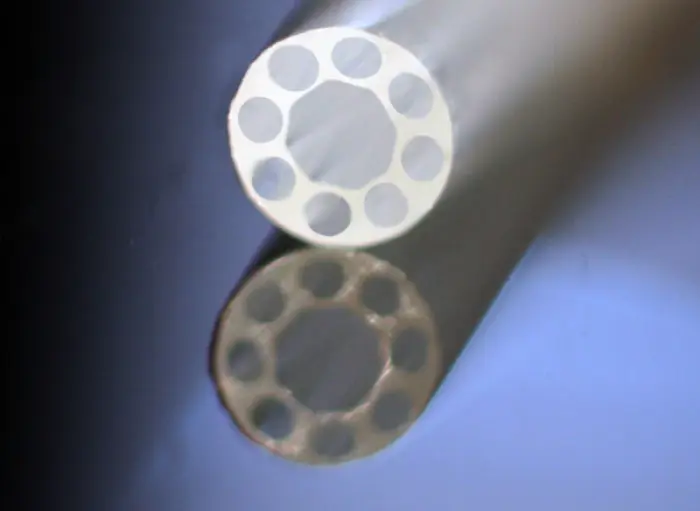

- Up to 14 lumens in a single tube

- Wall thicknesses down to 0.00075”

- Striping

- Coated wire

- Coil reinforced tubing or braid reinforced extrusion

- Annealing (as a post-extrusion service)

- Eccentric shaped (non-round) lumens and/or profiles

- Custom compounded resins

- Color matching

- Hydrophilic coating

- PTFE lined lumens

- and more

We create custom extrusions from a range of materials to meet customer design requirements. We work extensively with nylon, PEBA resin, polyester, polyurethane, polyethylene, and more, including custom compounds.

Custom extrusion development is at the core of our extrusion capabilities. We can deliver the custom medical extrusions or other custom extrusions you need in as little as three days.

Contact Duke Extrusion to learn more about the Custom Medical Extrusions we offer

Need your products quick? Duke Extrusion has you covered with our ultra-fast shipping times. Our stock tubing products, ship within 24 hours of purchase and braided standard tubing ships within 48 hours of order placement! At Duke Extrusion, we make purchasing medical-grade tubing easy with short lead times and quick, convenient, and hassle-free shipping. It’s not just stock products that ship with industry best lead times, custom extrusion and rapid customized catheter products are also provided with the shortest lead times available and personalized service. That’s the Duke difference!Get a quote on the custom extrusion your application requires, or contact us at 831-420-1104 to learn more. Need something customized to your specific needs? Visit Duke Empirical to see our in-house capabilities.