Medical Extrusion Materials

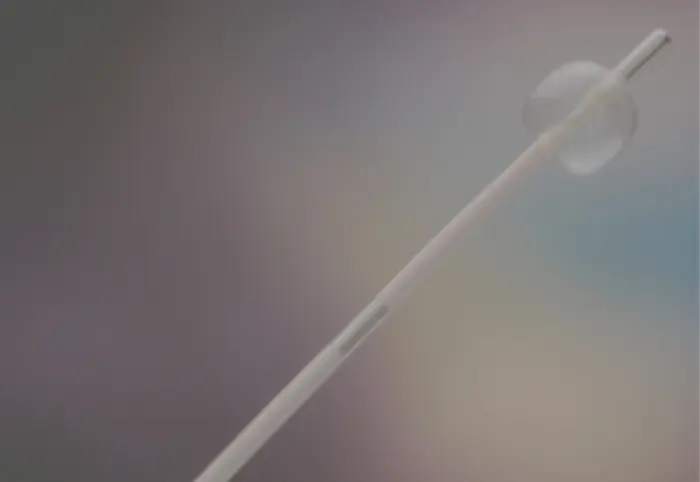

The medical industry can require complex devices that need high precision processes to produce. To manufacture medical tubing and catheters that meet both the needs of the patients and the industry regulations, Duke Extrusion relies on custom extrusion processes.

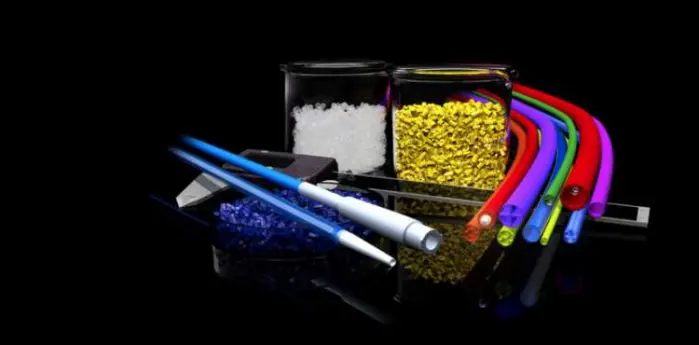

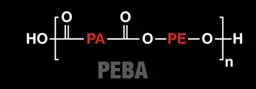

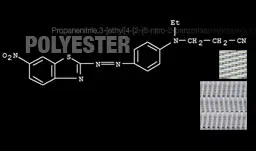

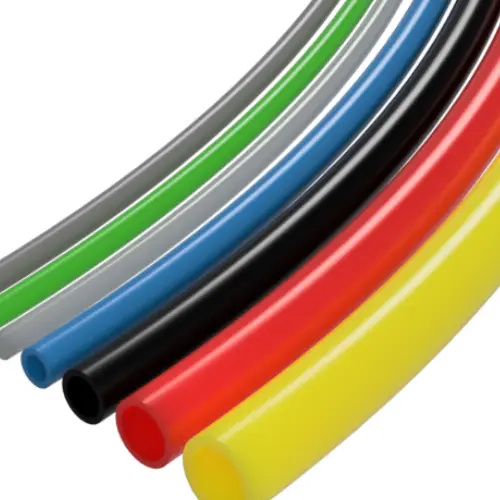

Duke Extrusion processes a vast array of thermoplastic polymers as extrusion materials. We work with common thermoplastic resins as well as high performance and custom-compounded resins. Our product application engineers will recommend materials based on your application.

Medical Tubing Material Options

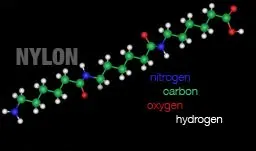

Our material experts partner with the world’s best material manufacturers to provide you the latest in polymer technology. Duke Extrusion offers many material options from nylon to polyester.

In addition to being experts in processing a wide range of materials, we also assist with the development of new material formulations to enable next-generation, market-leading products. We can supply medical tubing or catheter materials with unique additives such as:

- Nanoparticles

- Silver ions

- Light and heat stabilizers

- Lubricious agents

- Radiopacifiers

- Antimicrobial agents

- and more

Extrusion materials can be formulated to match your unique requirements, or we can recommend custom solutions to optimize the performance of your products.

What Material is Right for Your Application?

When deciding on the medical tubing materials for your applications, there are a number of important factors to consider. Using the wrong materials can chemically alter drugs and medicines or even cause them to bind to the tubing walls. Consider the following factors as they relate to your purpose:

Medical Tubing Strength

Depending on your needs, the medical tubing you choose may need added strength or durability. Different materials can offer different levels of abrasion and kink resistance. Polyurethane tubing material, for example, can be tackier than other materials, and, unless another material is added, can be more prone to tangles. It makes a great catheter material, however, because it softens with body heat.

Catheter and Tubing Materials Cost

Some materials are more expensive than others. PVC is one of the most cost-effective materials, and it still offers a variety of great benefits. The material you choose will ultimately depend on your needs balanced against your budget.

Medical Industry Compliance

There are many certifications and regulations, particularly in the medical industry, that your medical tubing materials need to meet to be safe. These regulations can differ depending on your applications. If your tube is exposed to X-ray radiation, for example, you can’t use materials that are radiopaque because it would result in an unacceptable image.

Custom Medical Extrusion Services from Duke Extrusion

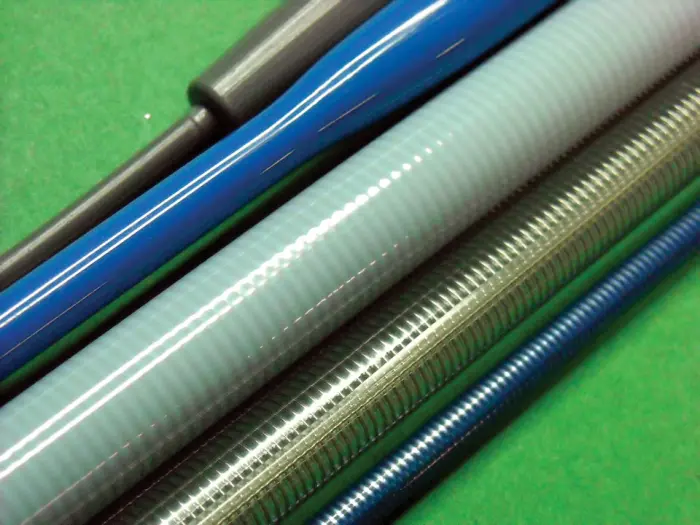

With our custom co-extrusion process, we can combine the beneficial properties of two materials by extruding them at the same time into a single tube. The materials can be arranged in concentric tube-on-tube configurations, or with striping of the materials in a single lumen for added benefits. In multi-lumen coextrusions, we can isolate materials to specific areas of the tubing’s cross-section.

In addition to co-extrusion, we also offer other custom extrusion services, including:

- Custom Single Lumen Tubing

- Multi-Lumen Tubing

- Taper/Bump Tubing

- Overjacketing

- Solid Rod Extrusions

- And more

Medical Tubing Applications

As one of the industry’s leading medical tubing suppliers, we manufacture tubing and catheters that meet a variety of unique needs. We work with you to match your design requirements for applications such as:

- Catheters

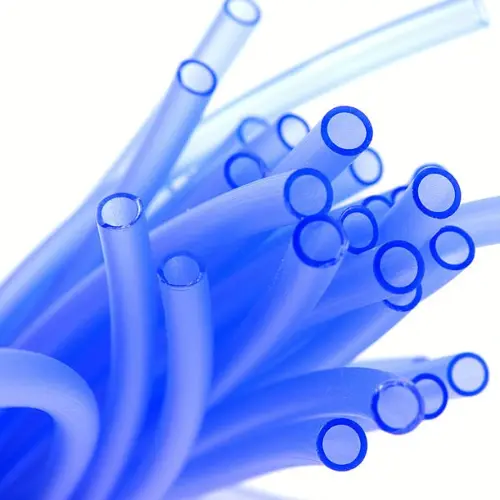

- Intravenous (IV) tubing

- Fluid transfers

- Infusion tubing

- Nasogastric tubes

- Anesthesia

- Hemodialysis tubing

- Oxygen

Contact Duke Extrusion for Medical Tubing Materials

Visit our stock tubing store or contact us to discuss your catheter material or medical tubing material requirements. Sill have questions about the thermoplastic extrusion materials we work with? Need something customized to your specific needs? Visit Duke Empirical to see our in-house capabilities.

Need your products quick? Duke Extrusion has you covered with our ultra-fast shipping times. Our stock tubing products, ship within 24 hours of purchase and braided standard tubing ships within 48 hours of order placement! At Duke Extrusion, we make purchasing medical-grade tubing easy with short lead times and quick, convenient, and hassle-free shipping. It’s not just stock products that ship with industry best lead times, custom extrusion and rapid customized catheter products are also provided with the shortest lead times available and personalized service. That’s the Duke difference!