Value Added Services

Enhance Your Medical Tubing with Duke Extrusion's Value-Added Services

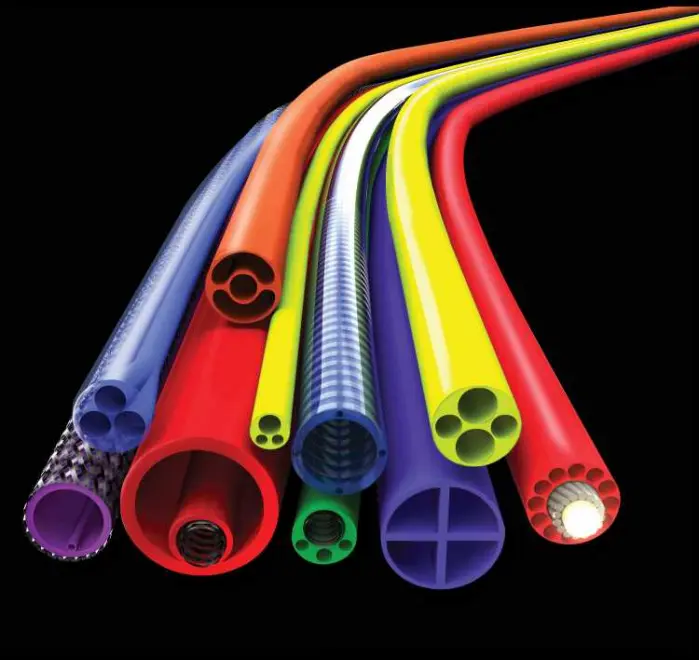

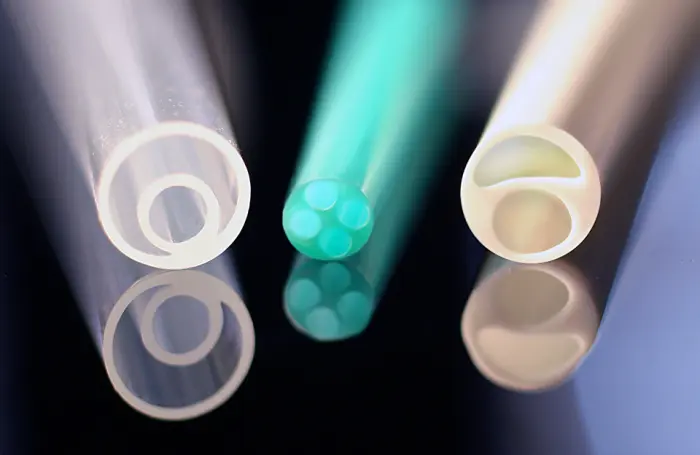

At Duke Extrusion, we understand that precision and performance are paramount in medical device manufacturing. Our comprehensive suite of value-added services is designed to elevate your medical tubing and catheter products, ensuring they meet the highest standards of quality and functionality. From advanced coatings to intricate reinforcements, our services are tailored to meet your specific application requirements.

Our Comprehensive Value-Added Services

Explore our range of specialized services that add value to your medical tubing solutions:

Actuation Cables & Wire

Enhance the functionality of your devices with our precision-engineered actuation cables and wires, designed for reliable performance in complex medical applications.?

Catheter Tipping

Achieve smooth and atraumatic catheter tips through our advanced tipping processes, ensuring patient comfort and device efficacy.?

Custom Pad Printing Services

Customize your medical tubing with high-quality pad printing, offering clear and durable markings for identification and branding purposes.?

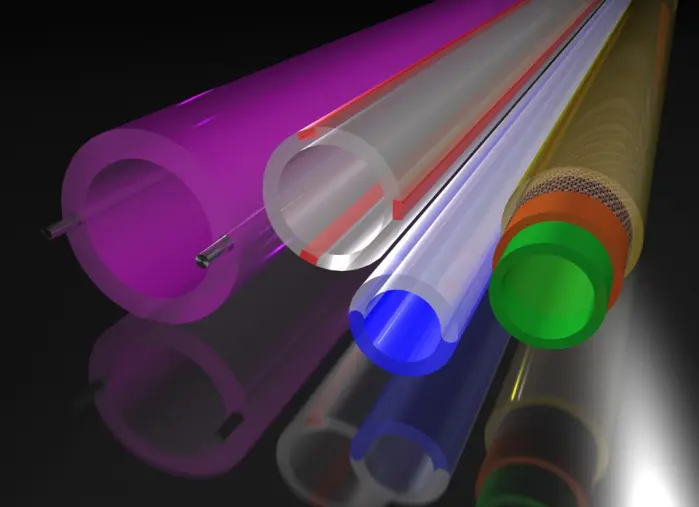

FEP Liners

Incorporate FEP liners into your tubing for enhanced chemical resistance and reduced friction, ideal for demanding medical environments.?

Hole Punching

Utilize our precise hole punching services to create openings in tubing for various applications, maintaining structural integrity and performance.?

Hydrophilic Coatings

Apply hydrophilic coatings to your medical tubing to reduce friction, facilitating smoother insertion and navigation within the body.?

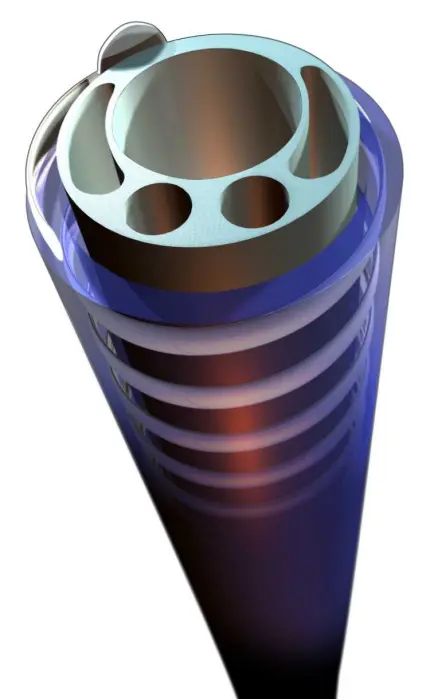

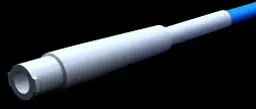

Longitudinal Reinforcement

Strengthen your tubing with longitudinal reinforcement, enhancing pushability and torque response for improved device control.?

Surface Treatment

Improve bondability and adhesion properties through our surface treatment processes, including plasma and corona treatments.

Tube Forming

Achieve complex shapes and configurations with our tube forming services, tailored to meet specific design and functional requirements.

Tubing Overmolding

Enhance the durability and functionality of your tubing assemblies through overmolding, providing seamless integration of components.?

Why Choose Duke Extrusion for Value-Added Services?

-

Integrated Solutions: Our value-added services are seamlessly integrated into our manufacturing processes, ensuring consistency and quality.?

-

Customization: We offer tailored solutions to meet your unique specifications, from material selection to final assembly.?

-

Expertise: With years of experience in medical tubing manufacturing, our team provides insights and guidance to optimize your products.

-

Quality Assurance: Operating within an EN 13485 certified quality system, we adhere to stringent standards to deliver reliable and safe medical components.

Ready to Enhance Your Medical Tubing?

Partner with Duke Extrusion to leverage our comprehensive value-added services, designed to elevate the performance and reliability of your medical devices. Contact us today to discuss your project requirements and discover how we can support your product development goals. In addition to that, visit Duke Empirical to see our in-house capabilities.